Features

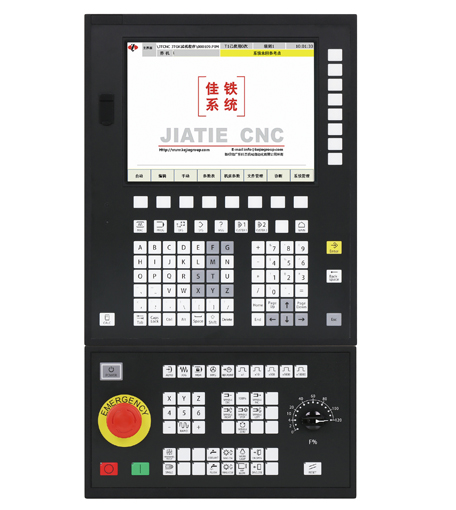

JT-810 is a high-end intelligent CNC controller researched and developed by JIATIE. It can be used in high speed engraving and milling machine, vertical machining center, drilling and milling center, 5-axis or 4-axis linkage machine, etc.

The controller is based on Intel's high-performance quad-core processor and is equipped with DSP and FPGA modules to perfectly realize real-time motion control technology and big data processing functions.

The human machine interface (HMI) is simple and easy to use. It's convenient for users to learn and master the machine operation quickly. The controller panel is in professional and high-end design, which is reliable, easy to use and with strong expandability. It's suitable for customization in different industries.

The controller is equipped with functions of S-shaped acceleration and deceleration control, high-speed high-precision contour accuracy control and 5-axis RTCP control. It can satisfy with various processing requirements of high speed, high precision, multi-axis linkage, etc.

JT-810 controller adopts an open architectural design with strong compatibility and openness. It supports functions of CCD image recognition, probe on-machine inspection/detection, machines interconnection, file sharing, remote monitoring and diagnosis, production data statistics, etc. It provides the machine with platform and comprehensive guarantee for realizing the Internet of Things, datamation and intelligence.

400-889-8833

400-889-8833

Download

Download Back

Back Service Hotline

Service Hotline